The Future of Herbal Extraction: Embracing Zero Residue Methods

Understanding Extraction Methods in Natural Products

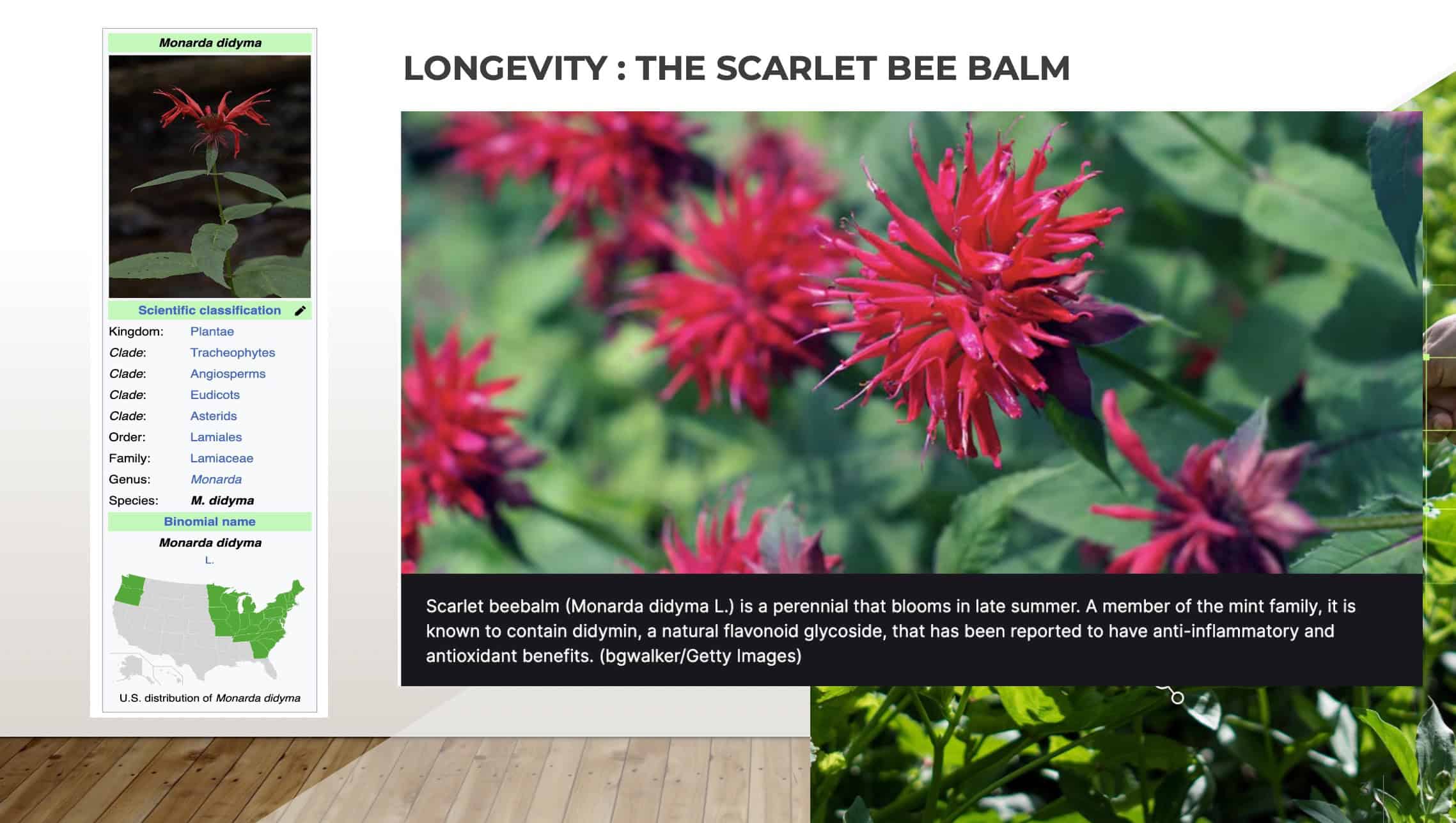

The process of extracting bioactive compounds from natural sources forms the foundation of the nutraceutical industry. When you consider the supplements you recommend to clients seeking better health outcomes, have you ever thought about how these ingredients are obtained? Extraction is the critical process that separates valuable compounds from their natural matrices, but the environmental footprint of these techniques varies dramatically.

Traditional extraction methods often rely on chemical solvents like hexane, acetone, or methanol. These processes, while efficient, can generate significant waste streams and potentially harmful emissions. More concerning is that residual solvents may remain in the final product, raising questions about long-term safety profiles. That’s clear from a technical standpoint, but have you ever considered that the very supplements intended to improve health might carry an environmental burden that ultimately affects public health?

Sustainable extraction alternatives have emerged as the nutraceutical industry evolves toward greater environmental responsibility. Methods such as supercritical CO2 extraction, enzyme-assisted extraction, and water-based techniques significantly reduce environmental impact while often preserving more of the natural compound integrity. These processes minimize waste generation, reduce energy consumption, and eliminate toxic solvent use – creating a truly sustainable approach to obtaining nature’s most valuable compounds.

Vertical Farming: Revolutionizing Botanical Extraction

Controlled Environment Agriculture for Superior Botanicals

When your clients ask about the purity and potency of plant-based supplements, vertical farming offers a compelling narrative. This innovative cultivation method represents a paradigm shift in how botanical ingredients are sourced for nutraceutical applications. Unlike traditional agriculture, vertical farming creates precisely controlled environments that optimize plant growth without pesticides, dramatically reducing water usage by up to 95% compared to conventional farming.

The environmental benefits extend beyond water conservation. Vertical farming significantly reduces land use pressure, a critical factor as agricultural expansion drives deforestation globally. By growing plants in stacked layers using artificial lighting and controlled nutrition delivery, these systems can produce botanical materials with consistent phytochemical profiles regardless of season or climate disruptions.

For nutraceutical extraction, this translates to standardized starting materials with higher concentrations of desired compounds. The controlled conditions eliminate the variability that often plagues wild-harvested or field-grown botanicals, allowing for more efficient extraction processes with higher yields. This means less waste and more predictable outcomes – a win for both manufacturers and consumers seeking reliable health benefits.

Reduced Carbon Footprint in Plant-Based Extractions

The proximity advantage of vertical farming creates another significant environmental benefit. By locating production facilities near extraction and manufacturing centers, companies can drastically reduce transportation emissions associated with raw material sourcing. This localized supply chain represents a marked improvement over traditional models that often involve shipping botanical materials across continents.

Building sustainable extraction systems around vertical farming creates a closed-loop approach where water and nutrients are recycled, organic waste is composted, and renewable energy powers both cultivation and extraction processes. This integrated model minimizes environmental impact at every stage while maximizing the quality and consistency of the extracted compounds.

Natural Extraction Technologies: Preserving Planetary and Human Health

The environmental impact of extraction extends beyond the immediate processing facilities to broader ecological considerations. Traditional wild harvesting of botanical materials can lead to overharvesting of endangered species and habitat disruption. Advanced cultivation methods coupled with efficient, low-impact extraction technologies address these concerns by reducing pressure on wild plant populations.

Water consumption represents another significant environmental concern in extraction processes. Conventional methods can require substantial volumes of water, both in the extraction itself and in subsequent cleaning operations. Innovative companies are implementing water recycling systems and developing solvent-free extraction methods that dramatically reduce this footprint while simultaneously improving extract purity.

Energy efficiency in extraction processes has also seen remarkable improvements. Traditional heat-based extraction methods consume significant energy, contributing to greenhouse gas emissions. Newer technologies including ultrasound-assisted extraction, pulsed electric field extraction, and microwave-assisted processes have demonstrated energy reductions of up to 70% while often improving extraction efficiency and maintaining the integrity of temperature-sensitive compounds.

The environmental benefits of advanced extraction methods extend to the final product quality as well. By avoiding harsh chemicals and excessive heat, these gentle approaches preserve more of the natural compound structures and beneficial synergistic relationships between plant constituents. This means nutraceutical products that more closely reflect the natural complexity of plant materials – potentially offering greater bioactivity and fewer unwanted side effects for your clients.

Our Key Areas of Expertise

The Interconnected Impact of Extraction Methods on Health Products

Environmental Footprint Affects Bioactive Quality

The environmental impact of extraction processes extends far beyond the immediate manufacturing concerns, creating a complex web of interconnections that ultimately affect the bioactive compounds you consume in supplements. When producers choose sustainable extraction methods, they’re not just making an ecological choice—they’re fundamentally altering the quality profile of the final nutraceutical products.

Consider the production chain of a typical plant-based supplement. Traditional extraction methods often employ petroleum-derived solvents that can leave residues in the final product, potentially introducing toxins into your system over time. These same solvents, when improperly disposed of, contaminate soil and groundwater systems, creating a cyclical problem where environmental degradation eventually impacts human health through the food chain. You might be seeking health benefits from supplements while unknowingly exposing yourself to compounds from environmentally damaging extraction processes.

The relationship between extraction methods and product efficacy becomes particularly evident when examining oxidative stability. Harsh extraction conditions can trigger degradation reactions that not only diminish the potency of desired compounds but can also generate potentially harmful oxidation products. This is especially concerning for sensitive bioactives like polyunsaturated fatty acids and certain antioxidant compounds that readily undergo oxidation when exposed to heat, oxygen, and light during aggressive extraction processes.

Vertical Farming Integration Enhances Extraction Outcomes

The marriage between vertical farming technologies and gentle extraction methods represents a significant advancement in sustainable nutraceutical production. This integrated approach addresses multiple environmental concerns simultaneously while enhancing product quality throughout the value chain.

Vertical farming’s controlled environment offers unprecedented advantages for subsequent extraction processes:

- Consistent phytochemical profiles regardless of season

- Elimination of pesticide residues that would otherwise require extensive purification

- Year-round production that reduces the need for preservatives and stabilizers

- Optimized growth conditions that can enhance the concentration of target compounds

When botanical materials from vertical farming systems enter the extraction pipeline, their uniformity and purity allow for more precise process parameters. This predictability enables manufacturers to use gentler extraction conditions while maintaining yield efficiency—reducing energy consumption without sacrificing product quality.

The plant metabolites produced under these optimized growing conditions often show enhanced profiles compared to conventionally grown counterparts. Research demonstrates that controlled stress factors in vertical farming can stimulate the production of beneficial secondary metabolites, resulting in starting materials with higher concentrations of desirable compounds. This upstream optimization reduces the extraction intensity needed downstream, creating an environmentally virtuous cycle.

Nanotechnology Applications Transform Extraction Efficiency

The integration of nanodelivery systems with sustainable extraction technologies has revolutionized how we approach bioactive compound isolation and delivery. These advanced systems not only improve the efficiency of the extraction process itself but also enhance the bioavailability of the extracted compounds in the final product.

Traditional extraction often requires excessive processing to achieve adequate bioavailability, resulting in higher energy consumption and waste generation. Nano-enabled extraction technologies address this challenge by:

- Reducing solvent requirements through targeted extraction approaches

- Lowering processing temperatures, preserving thermolabile compounds

- Increasing extraction yields, minimizing raw material requirements

- Enabling water-based extraction of traditionally solvent-dependent compounds

The environmental benefits of these advancements extend throughout the product lifecycle. For example, nanostructured extraction media can be reused multiple times, dramatically reducing waste streams. Meanwhile, the resulting plant-derived exosomes and other nanoscale delivery vehicles improve cellular uptake of nutraceutical compounds—meaning smaller doses can achieve equivalent or superior health outcomes.

This efficiency translates directly to reduced ecological pressure across the supply chain. When you require less raw material to achieve the same health benefit, you’re inherently reducing the environmental footprint of cultivation, processing, packaging, and transportation.

Biodiversity Conservation Through Advanced Extraction

The relationship between extraction methods and biodiversity conservation represents another crucial interconnection in sustainable nutraceutical production. Traditional wild harvesting for valuable botanical compounds has led to significant pressure on natural plant populations, with some medicinal plant species now threatened with extinction due to overharvesting.

Advanced extraction technologies help address this challenge through:

- Higher extraction efficiency requiring less raw material

- Ability to utilize cultivated alternatives instead of wild-harvested species

- Capacity to extract valuable compounds from previously unused plant parts

- Technology to valorize agricultural by-products as extraction sources

These advancements support the preservation of natural ecosystems while maintaining access to valuable bioactive compounds. Companies implementing selective natural extraction processes can significantly reduce pressure on wild plant populations while still delivering high-quality nutraceutical ingredients.

The environmental benefits extend to broader ecosystem services as well. When extraction technologies enable the utilization of agricultural waste streams as source material, they transform what would be environmental burdens into valuable resources. This circular approach reduces the carbon footprint associated with waste management while simultaneously decreasing demand for purpose-grown botanical materials.

Regulatory Frameworks Driving Sustainable Extraction

The regulatory landscape surrounding extraction technologies continues to evolve, with increasing emphasis on environmental impact assessments and sustainability criteria. Forward-thinking companies are proactively adopting green extraction principles, not only to comply with current regulations but to position themselves advantageously as standards become more stringent.

These regulatory pressures have accelerated research and development in areas like:

- Energy-efficient extraction technologies

- Solvent-free and reduced-solvent methodologies

- Circular economy approaches to extraction waste

- Life cycle assessment of extraction processes

The resulting innovations benefit both environmental outcomes and product quality profiles. When manufacturers embrace these sustainable approaches, they often discover that environmentally responsible extraction also yields superior products with enhanced stability, purity, and bioactivity.

R&D Consultancy

Discover how PhNóva’s R&D Consultancy can help transform your idea into a market-ready solution — with expert support in formulation, regulatory compliance, and innovative delivery systems to give your product a competitive edge.

FAQ's about The Future of Herbal Extraction: Embracing Zero Residue Methods

Get in Touch with PhNóva

Have questions or need expert guidance? Contact us today — our team is ready to assist you with tailored solutions for your formulations.

30/03/2025