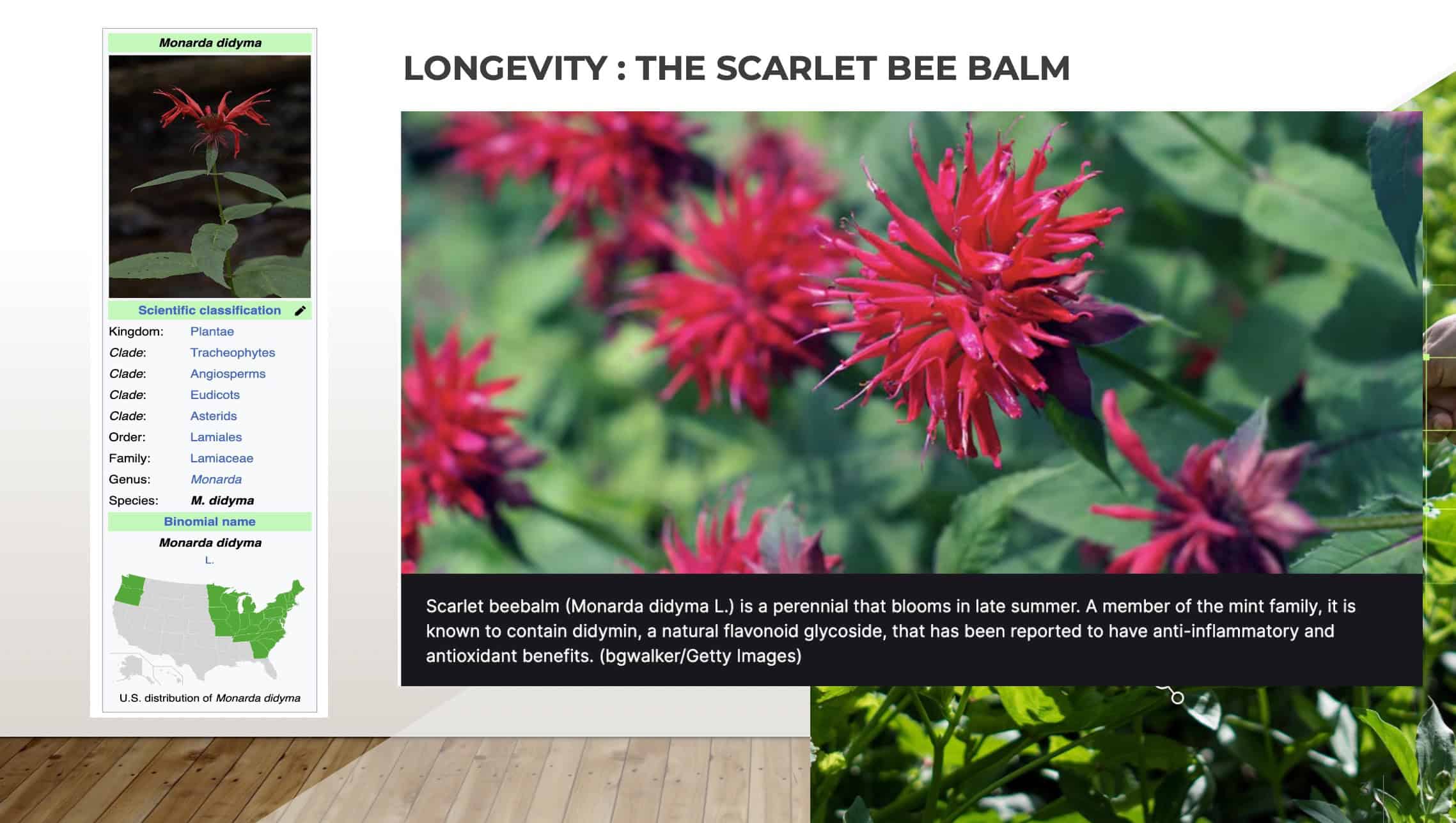

Sustainable Herb Farming: Practices That Protect Our Planet

Understanding Zero-Waste Extraction in Modern Nutraceuticals

Zero-waste extraction techniques represent a paradigm shift in how bioactive compounds are isolated from natural sources. These innovative methodologies aim to eliminate waste throughout the entire extraction process, from raw material selection to final product formulation.

You might wonder why this matters in the nutraceutical industry. Consider this: traditional extraction methods often use significant quantities of solvents, energy, and raw materials, with utilization rates sometimes as low as 5-10% of the original biomass. That’s a staggering amount of waste!

But have you ever considered that the very compounds being discarded might hold additional health benefits? Zero-waste extraction approaches this challenge by viewing “waste” not as something to discard, but as a resource to be utilized. This circular economy approach enhances sustainability while maximizing the value derived from each natural resource.

The significance extends beyond environmental considerations. Zero-waste extraction typically yields higher concentrations of bioactive compounds, enhances their bioavailability, and preserves their natural synergistic effects. This translates to nutraceuticals with improved efficacy and broader spectrum health benefits. For professionals developing products for clients with specific health needs, this means more effective solutions with reduced environmental impact.

Our Key Areas of Expertise

The Integration of Zero-Waste Extraction in Nutraceutical Production Systems

Revolutionizing the Bioactive Supply Chain

When examining modern nutraceutical production, zero-waste extraction represents more than just an isolated technique—it transforms the entire value chain. You can see this integration across multiple stages of production, from raw material sourcing to final product formulation.

Traditional extraction methods often create significant byproducts that require disposal, contributing to environmental burdens and reduced economic efficiency. By implementing circular approaches, manufacturers can redirect what was once considered waste into valuable inputs for secondary processes.

For example, after extracting primary compounds like Superoxide Dismutase (SOD) from plant materials, the remaining biomass can be processed further to isolate secondary metabolites or used as organic fertilizer in vertical farming operations. This creates a continuous loop where outputs from one process become inputs for another.

Environmental Impact and Sustainability Metrics

Zero-waste extraction directly influences the environmental footprint of nutraceutical production in several measurable ways:

- Reduced water consumption by up to 80% through solvent recycling and reclamation

- Minimized energy usage through optimized extraction temperatures and pressures

- Decreased carbon emissions from transportation by utilizing complete biomass

- Lower chemical waste through solvent-free methods like supercritical CO2 extraction

These benefits translate directly to your production costs and align with consumer expectations for environmentally responsible manufacturing practices.

Enhanced Efficacy Through Preservation of Bioactive Complexes

When you implement zero-waste methodologies, you’re not just saving resources—you’re often preserving the natural synergistic relationships between compounds. This has profound implications for the efficacy of final products.

Plant-derived exosomes and other complex bioactive structures can be damaged or lost during aggressive extraction processes. Zero-waste techniques that employ gentler methods like subcritical water extraction better maintain these delicate structures, resulting in products with enhanced bioavailability and efficacy.

A comparative analysis of traditional versus zero-waste extraction shows:

| Extraction Parameter | Traditional Method | Zero-Waste Method | Impact on Product Efficacy |

|---|---|---|---|

| Bioactive retention | 60-75% | 85-95% | Higher potency per dose |

| Native structure preservation | Moderate | High | Enhanced absorption |

| Co-factor retention | Low | High | Improved synergistic effects |

| Processing temperature | Often high | Generally lower | Better thermolabile compound preservation |

Integration with Vertical Farming Systems

The connection between zero-waste extraction and vertical farming botanics creates particularly powerful synergies. When you cultivate plants in controlled environments, you can standardize their phytochemical profiles and optimize them for specific bioactive compounds.

This controlled cultivation allows for:

- Precise timing of harvest to maximize target compound concentration

- Reduced variability in raw material composition

- Year-round availability of consistent botanicals

- Elimination of pesticides and environmental contaminants

After extraction, the spent biomass can be composted and returned to the vertical farming system, creating a closed-loop nutrient cycle that dramatically reduces input requirements.

Nanodelivery Systems and Extraction Efficiency

The advancement of nanodelivery systems in nutraceuticals has created new demands for highly purified bioactives. Zero-waste extraction meets this need by providing methods that yield higher purity compounds while eliminating process waste.

For professionals developing exosome-based formulations, this means you can achieve the required purity standards without generating excessive waste streams. The precision of modern zero-waste techniques allows for selective isolation of specific compounds while preserving others for secondary product lines.

Quality Control Advantages in Zero-Waste Systems

Implementing zero-waste extraction provides significant advantages for quality control in nutraceutical production. When you utilize the complete spectrum of compounds from a botanical source, you create multiple checkpoint opportunities throughout the process.

This comprehensive approach allows for:

- Better traceability of compounds through the production chain

- Multiple quality validation steps at different extraction phases

- Improved detection of contaminants or adulterants

- More stable and predictable final product specifications

For manufacturers of food-derived products with health benefits, these quality control advantages translate directly to more consistent efficacy and safety profiles.

Economic Benefits Beyond Sustainability

While environmental considerations often drive the initial interest in zero-waste extraction, the economic benefits make the business case compelling. You can achieve significant cost reductions through:

- Decreased raw material requirements per unit of active compound

- Reduced waste disposal costs

- Creation of secondary revenue streams from previously discarded materials

- Lower regulatory compliance expenses related to waste management

These economic advantages allow manufacturers to invest more in research and development, creating even more innovative and effective nutraceutical formulations.

R&D Consultancy

Discover how PhNóva’s R&D Consultancy can help transform your idea into a market-ready solution — with expert support in formulation, regulatory compliance, and innovative delivery systems to give your product a competitive edge.

FAQ's about Sustainable Herb Farming: Practices That Protect Our Planet

Get in Touch with PhNóva

Have questions or need expert guidance? Contact us today — our team is ready to assist you with tailored solutions for your formulations.

27/03/2025