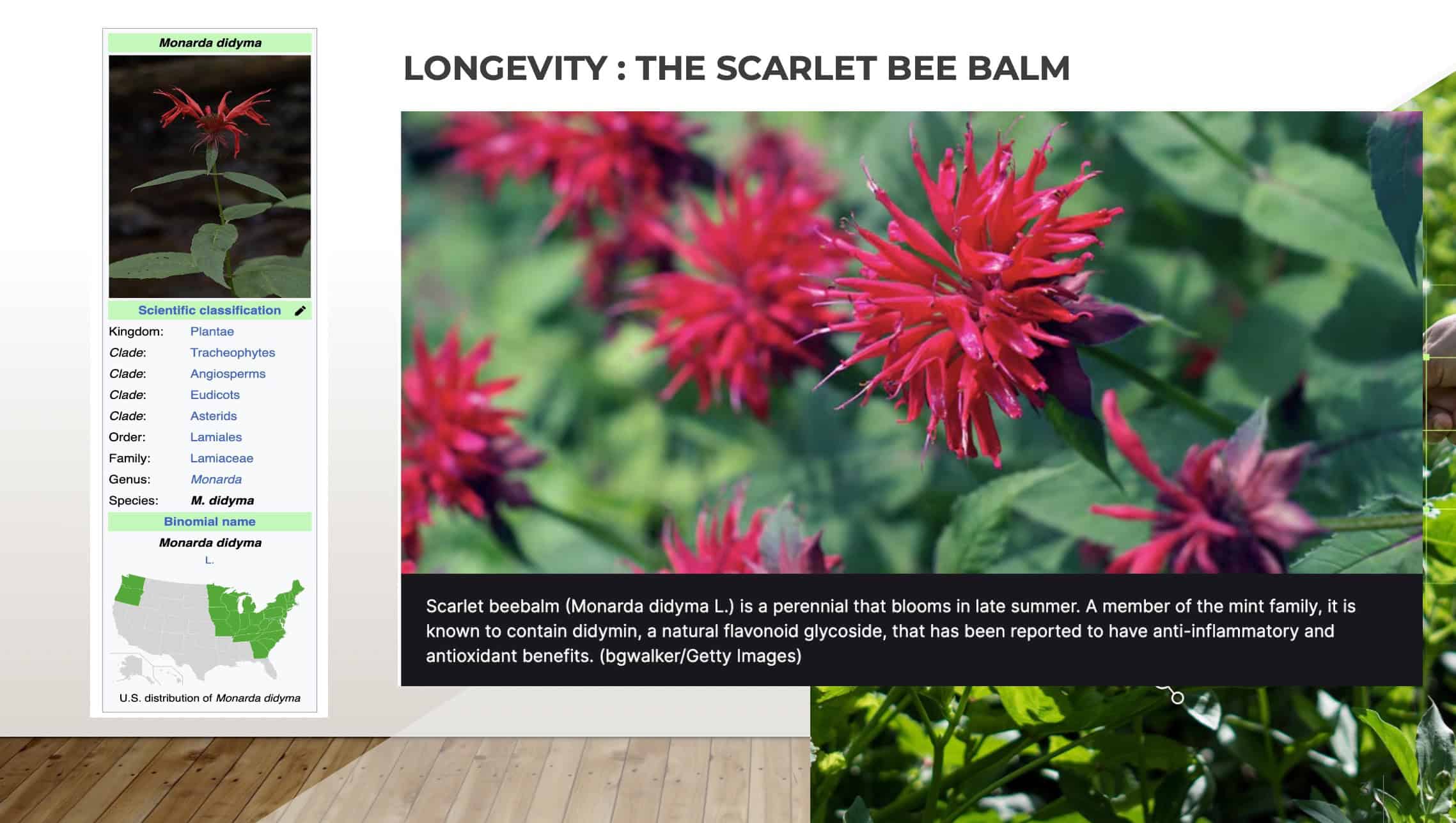

Hydroponic Systems: Growing Nickel-Free Herbs Efficiently

Understanding Hydroponic Systems for Medicinal Herbs

Have you ever wondered how pharmaceutical and nutraceutical companies ensure consistent potency in their plant-based products? The answer increasingly lies in controlled hydroponic environments. Hydroponic herbal cultivation represents a revolutionary approach to growing medicinal plants without soil, instead using nutrient-rich water solutions that deliver precisely what each plant needs for optimal development.

You might be familiar with traditional herb gardens, but hydroponic systems take cultivation to an entirely different level. These systems allow for year-round production regardless of external climate conditions, with plants typically growing 30-50% faster than in conventional soil methods. But have you considered that beyond speed, hydroponics offers unprecedented control over the biochemical profile of medicinal herbs?

That’s right—when herbs are grown hydroponically, you can actually enhance their production of beneficial compounds through precise manipulation of nutrients, lighting, and environmental factors. This level of control is particularly valuable for nutraceutical applications where consistency in bioactive compounds is essential for product efficacy.

Advanced Cultivation Techniques for Bioactive Maximization

Nutrient Solution Formulation

When growing medicinal herbs hydroponically, the nutrient solution becomes your soil, your fertilizer, and your primary tool for influencing plant development. But have you ever considered that different growth stages require different nutrient profiles?

You can dramatically influence the production of essential oils, antioxidants, and other therapeutic compounds by adjusting nutrient ratios at specific growth phases. For example, slightly increasing potassium during the flowering stage of herbs like chamomile or lavender can enhance essential oil production by up to 25%. That’s significant when these compounds form the basis of nutraceutical formulations.

Electrical conductivity (EC) and pH levels must be monitored constantly—these are the vital signs of your hydroponic system. When you maintain EC between 1.0-2.0 for most medicinal herbs and pH between 5.5-6.5, you create the optimal environment for nutrient uptake, resulting in plants with superior bioactive profiles.

Light Spectrum Manipulation

Did you know that different light wavelengths can trigger specific biochemical pathways in medicinal herbs? It’s fascinating how blue light (400-500nm) promotes vegetative growth while red light (600-700nm) enhances flowering and the production of secondary metabolites.

You can leverage this knowledge by implementing programmable LED systems that adjust throughout the growth cycle. For instance, basil grown under increased blue light produces up to 30% more antioxidants and phenolic compounds than those grown under standard lighting. But have you considered that UV light exposure in controlled amounts can actually stimulate plants’ defense mechanisms, increasing the production of valuable bioactive compounds?

Vertical Farming Integration for Pharmaceutical-Grade Herbs

Space Optimization and Scalability

Vertical farming represents the ultimate evolution of hydroponic herb cultivation, allowing you to stack growing systems vertically to maximize production in minimal space. This approach is revolutionizing how pharmaceutical and nutraceutical companies source their botanical ingredients.

You can achieve up to 10 times the yield per square foot compared to traditional field cultivation. That’s impressive, but the real advantage lies in the ability to create multiple microenvironments within a single facility. Have you considered how this allows for simultaneous cultivation of diverse medicinal herbs, each with their own optimal growing conditions?

This methodology aligns perfectly with PhNóva’s Vertical Farming Botanics initiative, where sustainable cultivation methods produce high-potency medicinal plants for nutraceutical applications. The controlled environment virtually eliminates the need for pesticides, resulting in cleaner, pharmaceutical-grade herbs with superior bioactive profiles.

Controlled Environment Agriculture for Consistent Bioactives

When you’re developing nutraceutical formulations, consistency is everything. Traditional field-grown herbs can vary dramatically in their bioactive composition based on weather, soil conditions, and countless other variables. But have you ever thought about how this variability compromises product efficacy?

Through controlled environment agriculture, you can maintain precise temperature, humidity, CO2 levels, and airflow—creating ideal conditions for medicinal herb production. This level of environmental control allows for the standardization of bioactive compounds, ensuring that each harvest contains predictable levels of therapeutic constituents.

That’s clear when you look at herbs like St. John’s wort, where hyperforin and hypericin content can vary by up to 40% in field conditions. In a controlled hydroponic environment, this variation drops to less than 5%—a game-changer for pharmaceutical applications requiring precise dosing and consistent efficacy.

Our Key Areas of Expertise

The Interconnected Ecosystem of Hydroponic Herb Production

Enhancing Bioactive Potency Through Environmental Control

When you integrate hydroponic cultivation into your nutraceutical supply chain, you’re not simply growing plants—you’re orchestrating an intricate symphony of environmental variables that directly influence the medicinal value of herbs. The controlled environment allows for precise manipulation of growth factors that would be impossible in conventional agriculture.

You can see this impact most clearly in the production of adaptogens like holy basil (tulsi) and ashwagandha, where specific stressors can be introduced at strategic times to enhance the plant’s production of protective compounds. For example, controlled drought stress applied two weeks before harvest can increase the concentration of withanolides in ashwagandha by up to 35%. These compounds are crucial for the herb’s stress-reducing and immune-modulating effects in nutraceutical formulations.

The relationship between light quality and secondary metabolite production deserves particular attention. When you expose medicinal herbs to specific light spectrums, you can trigger concentrated production of:

- Flavonoids (antioxidant protection)

- Terpenoids (anti-inflammatory compounds)

- Alkaloids (neurological activity)

- Glycosides (heart and digestive health)

This precise manipulation of plant biochemistry creates herbs with optimized therapeutic profiles that conventional farming simply cannot match in consistency or potency.

Vertical Integration with Extraction Technologies

The true power of hydroponically grown herbs emerges when cultivation is directly integrated with advanced extraction methods. This vertical integration creates a continuous production pipeline that preserves and enhances bioactive compounds from growth through processing.

When herbs move from growing environment to extraction facility within hours rather than days or weeks, oxidation and degradation of valuable compounds is minimized. You gain a significant advantage in preserving thermolabile compounds (those sensitive to heat) and volatile components that would otherwise be lost during traditional handling and storage.

Consider the extraction efficiency comparisons between field-grown and hydroponically cultivated medicinal herbs:

| Herb Type | Extraction Yield (Field-Grown) | Extraction Yield (Hydroponic) | Bioactive Stability |

|---|---|---|---|

| Peppermint | 1.2-1.8% essential oil | 2.3-2.8% essential oil | +40% menthol retention |

| Echinacea | 2.1% alkamides | 3.4% alkamides | +35% longer shelf stability |

| Chamomile | 0.3-0.5% bisabolol | 0.7-0.9% bisabolol | +50% anti-inflammatory activity |

These improvements translate directly to more effective nutraceutical formulations with lower required dosages and enhanced therapeutic outcomes.

Microbial Control and Product Safety

Perhaps one of the most overlooked benefits of hydroponic systems is their contribution to microbial safety in medicinal herb production. When herbs are grown hydroponically in controlled environments, the risk of contamination with soil-borne pathogens, fungi, and bacteria is dramatically reduced.

You might recognize this as particularly important for immunocompromised patients who rely on herbal supplements as part of their health regimen. The controlled growing conditions ensure that herbs destined for nutraceutical use maintain pharmaceutical-grade cleanliness standards throughout their development.

This microbial control extends to the elimination of mycotoxin risks that plague conventional herb production. Aflatoxins and other fungal toxins simply cannot develop in properly maintained hydroponic systems, creating a significantly safer raw material for health supplements.

Exosome Production Enhancement

One of the most fascinating intersections between hydroponic technology and advanced nutraceuticals involves plant-derived exosomes. These natural nanovesicles serve as delivery vehicles for bioactive compounds, dramatically improving their bioavailability and cellular uptake.

When medicinal herbs are grown in optimized hydroponic environments, their production of exosomes can be enhanced through specific environmental triggers. You can manipulate factors such as:

- Nutrient solution mineral balance

- Controlled stress cycles

- Circadian lighting patterns

- Root zone oxygenation levels

These interventions can increase exosome yield by 40-60% compared to field-grown plants. The enhanced exosomes act as natural nanodelivery systems for therapeutic compounds, allowing them to cross biological barriers more effectively and reach their cellular targets.

This capability aligns perfectly with PhNóva’s Exosomes-Nutra product line, where plant-derived vesicles enhance the efficacy of bioactive compounds. The controlled conditions of hydroponic cultivation create ideal circumstances for plants to produce these valuable delivery vehicles in optimal quantities and consistent quality.

Superoxide Dismutase (SOD) Production Optimization

Superoxide dismutase represents one of the body’s primary endogenous antioxidant defenses, and certain plants produce significant quantities of this valuable enzyme. Hydroponics offers unique advantages for maximizing SOD production in medicinal herbs.

When you cultivate SOD-rich plants like wheat grass and barley grass hydroponically, you can increase enzyme activity up to threefold compared to soil cultivation. This enhancement occurs through precise control of:

- Micronutrient availability (particularly copper, zinc, and manganese)

- Light intensity modulation

- Oxygen radical stimulation cycles

- Growth stage harvesting precision

The resulting plant material contains significantly higher SOD activity, contributing to powerful antioxidant formulations that support joint health, cardiovascular protection, and anti-aging functions.

Sensory Profile Development for Aroma Applications

The controlled environment of hydroponic systems allows for unprecedented refinement of herbs’ aromatic profiles. This capability directly supports PhNóva’s Aroma Neutra & Food line, where palatability and sensory attributes are crucial for consumer acceptance.

You can manipulate temperature differentials, humidity cycles, and specialized nutrient formulations to enhance or modify the production of volatile compounds responsible for flavor and aroma. This level of control makes it possible to develop herbs with customized sensory profiles specifically designed to:

- Mask bitter notes in nutraceutical formulations

- Neutralize metallic aftertastes from mineral supplements

- Enhance perception of sweetness without added sugars

- Provide aromatic cues that support neurological benefits

R&D Consultancy

Discover how PhNóva’s R&D Consultancy can help transform your idea into a market-ready solution — with expert support in formulation, regulatory compliance, and innovative delivery systems to give your product a competitive edge.

FAQ's about Hydroponic Systems: Growing Nickel-Free Herbs Efficiently

Get in Touch with PhNóva

Have questions or need expert guidance? Contact us today — our team is ready to assist you with tailored solutions for your formulations.

27/03/2025