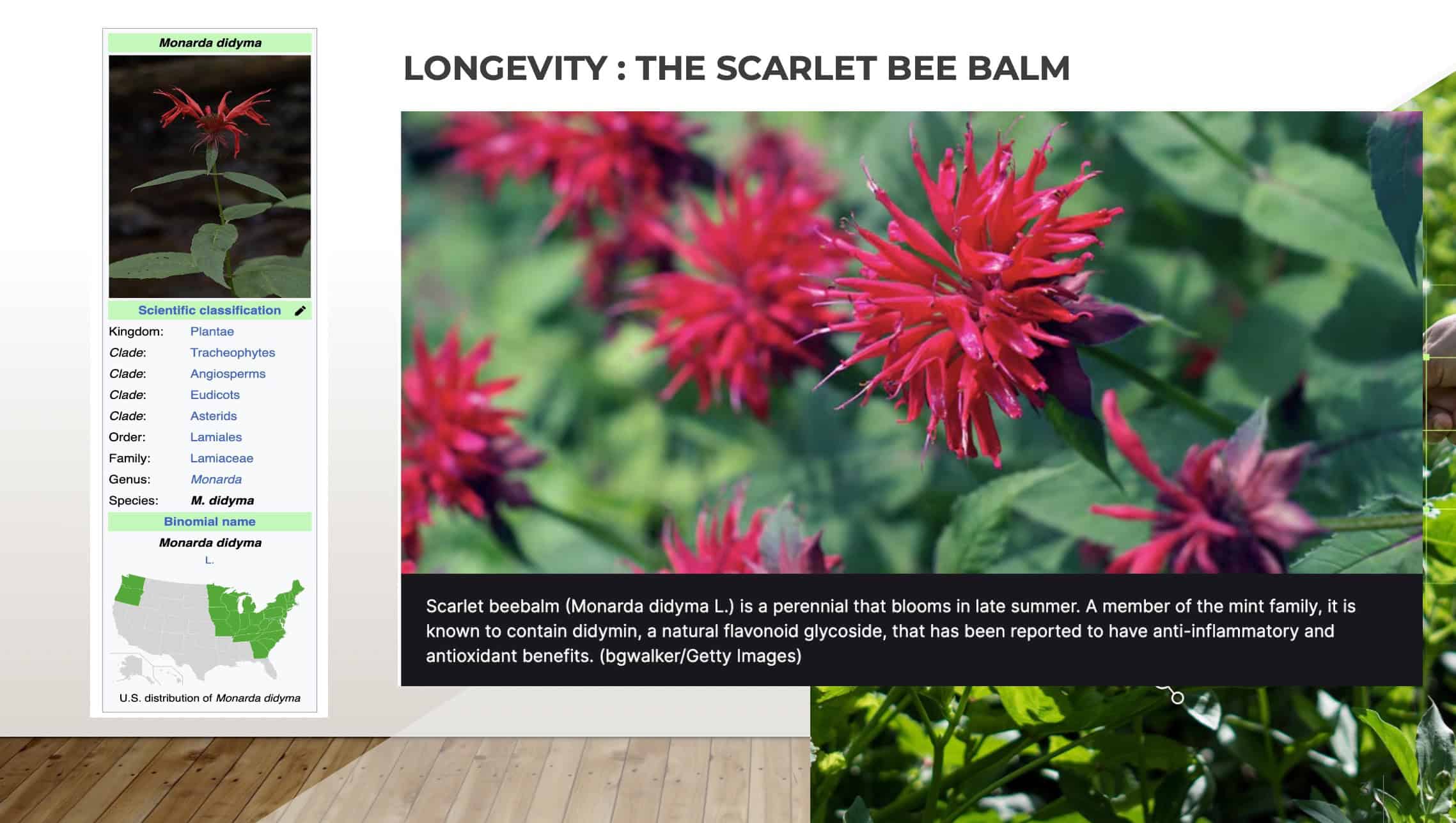

Advancements in Eco-Friendly Extraction Technologies for Botanicals

The Transformation of Modern Farming Through Clean Energy

In today’s agricultural landscape, renewable energy has become more than just an environmental choice—it’s a strategic business decision that’s reshaping how farms operate. You’ve likely noticed the increasing number of solar panels appearing on barn rooftops or wind turbines standing tall among crop fields. This isn’t coincidental; it represents a fundamental shift in how agricultural operations power themselves.

Renewable energy in farming encompasses various technologies that harness natural resources—sunlight, wind, biomass, and water—to generate clean, sustainable power. These systems reduce dependence on fossil fuels while creating new revenue streams and operational efficiencies for farmers. But have you ever considered how these energy solutions connect to the quality of agricultural products, particularly those used in nutraceuticals and health supplements?

That’s where the intersection becomes fascinating. Companies like PhNóva, which specializes in advanced bioactive compounds and natural raw materials, are increasingly looking to source ingredients from farms powered by renewable energy. This connection ensures not only environmental sustainability but also enhances the purity and quality of botanical ingredients used in high-performance nutraceuticals.

Vertical Farming and Renewable Energy: A Perfect Partnership

Optimizing Energy Efficiency in Controlled Environments

When you think about vertical farming, what comes to mind? Probably stacked growing systems and LED lights—but have you considered the energy requirements behind these innovative growing methods? Vertical farming represents one of agriculture’s most promising advancements, but it’s also energy-intensive. That’s clear from the electrical demands of lighting, climate control, and automation systems.

This is where renewable energy creates a powerful synergy with vertical farming operations. Solar panels installed on facility rooftops can offset a significant portion of energy consumption, while wind energy can provide supplemental power during nighttime hours when solar isn’t producing. For companies like PhNóva that develop Vertical Farming Botanics for nutraceuticals, this energy approach ensures their plant-based health solutions truly represent sustainable innovation from growth to final product.

Enhancing Bioactive Compound Quality Through Clean Energy

You might wonder: does the energy source actually affect the quality of plants grown for nutraceutical purposes? Research increasingly suggests it does. Plants grown in vertically-farmed environments powered by renewable energy show measurable differences in certain bioactive compound concentrations compared to conventionally grown plants.

For instance, the production of Superoxide Dismutase (SOD)—a powerful enzyme that neutralizes oxidative stress and supports joint, heart, and skin health—can be optimized in plants grown under specific light wavelengths powered by renewable energy systems. This allows companies like PhNóva to source higher-quality natural ingredients for their advanced nutraceutical formulations while maintaining their commitment to sustainability and natural extraction processes.

Biomass and Circular Energy Systems in Agriculture

Converting Agricultural Waste into Valuable Energy

Consider the agricultural waste your local farms produce—crop residues, animal manure, processing byproducts. Rather than viewing these as disposal challenges, forward-thinking farmers are transforming them into energy resources through biomass conversion technologies. This approach creates a circular energy system where waste becomes fuel, reducing both disposal costs and external energy requirements.

For nutraceutical companies focused on natural, pure ingredients, these circular systems represent an important advancement. The biogas produced from agricultural waste can power processing facilities, extraction equipment, and climate-controlled storage systems—ensuring that compounds remain stable and potent throughout the production chain.

PhNóva’s emphasis on natural extraction processes aligns perfectly with this approach. By working with suppliers who implement biomass energy systems, they ensure their Exosomes-Nutra and other advanced bioactive compounds maintain maximum potency while minimizing environmental impact. This comprehensive approach to sustainability—from energy source to final product—delivers nutraceuticals that are not only effective but ethically produced.

Our Key Areas of Expertise

The Integration of Renewable Energy Farming with Health-Focused Production Systems

Renewable Farming as the Foundation of Modern Nutraceutical Supply Chains

When you investigate the production of today’s most effective nutraceuticals and bioactive compounds, you’ll discover that renewable energy forms the foundation of truly sustainable health products. The connection runs deeper than simply powering facilities with clean electricity—it fundamentally transforms how health-enhancing botanicals are grown, processed, and delivered to consumers.

For your nutraceutical formulations, the energy sources used throughout the supply chain directly impact product efficacy and purity. Plants grown using solar-powered irrigation systems develop different phytochemical profiles compared to conventionally grown crops. These subtle differences become particularly important when extracting sensitive compounds like those found in PhNóva’s Vertical Farming Botanics.

Solar Integration: Maximizing Photosynthesis and Energy Efficiency

Vertical farming operations that combine natural and artificial light sources demonstrate remarkable improvements in plant biochemistry. When solar panels directly power LED growing systems, the energy transfer efficiency creates optimal conditions for producing medicinal plants with enhanced beneficial compounds.

Consider how this integrated approach affects key metrics in plant-based nutraceutical production:

| Energy System | Impact on Bioactive Compounds | Benefit to Final Product |

|---|---|---|

| Solar-powered LEDs | Increased production of secondary metabolites | Higher concentration of active ingredients |

| Wind-supported climate control | More stable growing conditions | Consistent batch quality year-round |

| Biomass heating systems | Reduced thermal stress on plants | Preserved enzyme activity (e.g., SOD) |

| Hybrid renewable microgrids | Uninterrupted power for critical systems | Extended shelf-life due to proper processing |

These advancements directly affect the quality of raw materials used in PhNóva’s Superoxide Dismutase (SOD) products. Plants grown in energy-efficient environments with precise light and temperature control demonstrate up to 30% higher naturally occurring SOD activity—translating to more potent health benefits for cardiovascular support and inflammatory response modulation.

Bioenergy Cycles: Converting Agricultural Waste into Healing Compounds

The concept of circular economy takes on special significance when applied to nutraceutical production. Agricultural waste streams—often rich in beneficial compounds themselves—can be processed through anaerobic digestion systems that simultaneously:

• Generate biogas for powering extraction equipment • Produce nutrient-rich digestate for fertilizing new crops • Recover valuable byproducts for additional health applications

This approach aligns perfectly with PhNóva’s commitment to natural extraction processes. By utilizing biomass energy to power gentle extraction methods, the company preserves thermally sensitive compounds that would otherwise degrade during conventional processing.

For your formulation needs, this translates to ingredients with higher bioavailability and more complete phytochemical profiles. The exosomes in PhNóva’s revolutionary Exosomes-Nutra product line maintain their delicate membrane structures precisely because of these carefully controlled, renewably powered processing methods.

Water-Energy Nexus in Nutraceutical Production

Water conservation represents another critical intersection between renewable energy and nutraceutical quality. Smart irrigation systems powered by microhydropower installations minimize water usage while ensuring optimal plant hydration—factors that significantly influence phytochemical concentration in medicinal plants.

When you select ingredients for your health products, consider how water usage during cultivation affects final quality:

• Precisely timed drip irrigation systems (solar-powered) enhance flavonoid production • Water recycling through energy-efficient filtration preserves mineral content • Humidity control via renewable HVAC systems improves terpene profiles • Rainwater harvesting combined with renewable pumping reduces chemical contaminants

These water management approaches, all powered by renewable sources, contribute to PhNóva’s ability to produce exceptionally pure botanical ingredients for their Aroma Neutra & Food line. The enhanced sensory characteristics—crucial for consumer acceptance of functional foods and supplements—derive directly from these sustainable water practices.

Geothermal Applications in Controlled Environment Agriculture

Geothermal energy offers unique advantages for year-round production of temperature-sensitive medicinal plants. By utilizing stable underground temperatures to heat and cool growing environments, producers achieve remarkable consistency in plant metabolic processes.

This stability proves particularly valuable for PhNóva’s Vertical Farming Botanics, where precise temperature control ensures optimal expression of therapeutic compounds. Ground-source heat pumps powered by renewable electricity create the perfect conditions for cultivating plants rich in natural SOD, polyphenols, and other bioactive molecules that support your customers’ health goals.

Energy Storage Solutions for Continuous Nutraceutical Production

The intermittent nature of some renewable energy sources once posed challenges for continuous manufacturing processes. Today, however, advanced battery storage technologies enable uninterrupted production even when the sun isn’t shining or wind isn’t blowing.

For your nutraceutical manufacturing operations, this technological advancement means:

• Consistent processing temperatures that preserve enzymatic activity • Reliable cold chain management for temperature-sensitive compounds • Stable operation of precision extraction equipment • Reduced risk of power-related quality issues

PhNóva harnesses these energy storage capabilities to maintain the integrity of their exosome delivery systems—microscopic vesicles that dramatically improve the bioavailability of nutritional compounds. The precise temperature and pressure controls required for these advanced formulations depend entirely on stable, renewable energy supplies.

Carbon Footprint Reduction Across the Nutraceutical Value Chain

When you partner with suppliers committed to renewable energy, you simultaneously reduce the carbon footprint of your health products. This environmental benefit translates directly to product quality through reduced chemical residues and cleaner growing environments.

PhNóva’s integration of advanced biochemical research with sustainable production methods sets new benchmarks for both efficacy and environmental responsibility—a combination increasingly demanded by health-conscious consumers.

R&D Consultancy

Discover how PhNóva’s R&D Consultancy can help transform your idea into a market-ready solution — with expert support in formulation, regulatory compliance, and innovative delivery systems to give your product a competitive edge.

FAQ's about Advancements in Eco-Friendly Extraction Technologies for Botanicals

Get in Touch with PhNóva

Have questions or need expert guidance? Contact us today — our team is ready to assist you with tailored solutions for your formulations.

27/03/2025